ISO 9001 Certification

ISO 9001 is an internationally recognized standard for quality management systems. The standard is generic in nature and caters to both the manufacturing and service industries.

Organizations that are certified to this standard reflect evidence of a business operation that is supported by a fundamental and robust quality management system platform.

GSCS provides quality service through competent auditing mechanism. Facility gains global recognition though the certificate.

ISO 14001 Certification

It provides practical tools for companies and organizations looking to identify and control their environmental impact and constantly improve their environmental performance.

Global Clients chose us in preference to others for a variety of reasons. In most cases it’s because they like our fair and practical approach throughout the entire certification process and how we understand and meet each individual client’s needs. In short the Quality of our Service.

ISO 45001 Certification

ISO 45001 is an internationally recognized standard for occupational health and safety. It exists to help all kinds of organizations put in place demonstrably sound occupational health and safety performance.

GSCS provides the level of quality certificate where facility can be ensured to function better.

ISO 22000 Certification

The ISO 22000 family of International Standards addresses food safety management. The consequences of unsafe food can be serious and ISO’s food safety management standards help organizations identify and control food safety hazards.

Why get certified?

As many of today’s food products repeatedly cross-national boundaries, International Standards are needed to ensure the safety of the global food supply chain.

ISO 27001 Certification

ISO 27001 is a specification for an information security management system (ISMS). An ISMS is a framework of policies and procedures that includes all legal, physical, and technical controls involved in an organization’s information risk management processes. Information may be printed or written on paper, stored electronically, transmitted by post or email, shown on films, or spoken in conversation.

ISO 50001 Certification

ISO 50001 Energy Management System certification, provides a framework for establishing energy management best practices to help organizations to improve their energy efficiency plus make a return on investment by implementing ISO 50001.

Who needs to be certified?

ISO 50001 provides a framework of requirements that help organizations: develop a policy for more efficient use of energy. fix targets and objectives to meet the policy. use data to better understand and make decisions concerning energy use and consumption.

ISO 13485 Certification

ISO 13485 Medical devices — Quality management systems — Requirements for regulatory purposes is an International Organization for Standardization (ISO) standard published for the first time in 1996; it represents the requirements for a comprehensive quality management system for the design and manufacture of medical.

ISO 28000 Certification

With increasing globalization, many companies rely on a supply chain that is on the other side of the world to ship parts, components, or finished products.

ISO 28000 offers organizations whose business relates to the logistics industry, a framework to identify each aspect that is critical to the security assurance of their supply chains. These include financing, manufacturing, and information management. Facilities for packing, storing, and transferring goods on their way to locations via various modes of transportation are also included in this standard.

ISO 26000 Certification

ISO 26000 is the designation of the future International Standard giving guidance on social responsibility (SR). It is intended for use by organizations of all types, in both public and private sectors, in developed and developing countries. It will assist them in their efforts to operate in the socially responsible manner that society increasingly demands. ISO 26000 contains guidance, not requirements, and therefore will not be for use as a certification standard like ISO 9001:2015 and ISO 14001:2015

ISO EN 20471

EN ISO 20471 is an international standard that imposes requirements on visible workwear for employees in high-risk areas. Today, in more and more industries, employees need to wear safety workwear with retro-reflective bands and fluorescent material to keep visibility intact. This applies to industries where a large part of the work takes place near airports, dual carriageways, traffic, cranes, and other motorized vehicles, as well as work that takes place in the dark.

GMP Certification

GMP refers to the Good Manufacturing Practice Regulations.

GMP certification is granted to manufacturing or service systems of organizations to certify that they engage with good manufacturing practices in their manufacturing or service processes, according to a Standard Code of Practice related to their business.

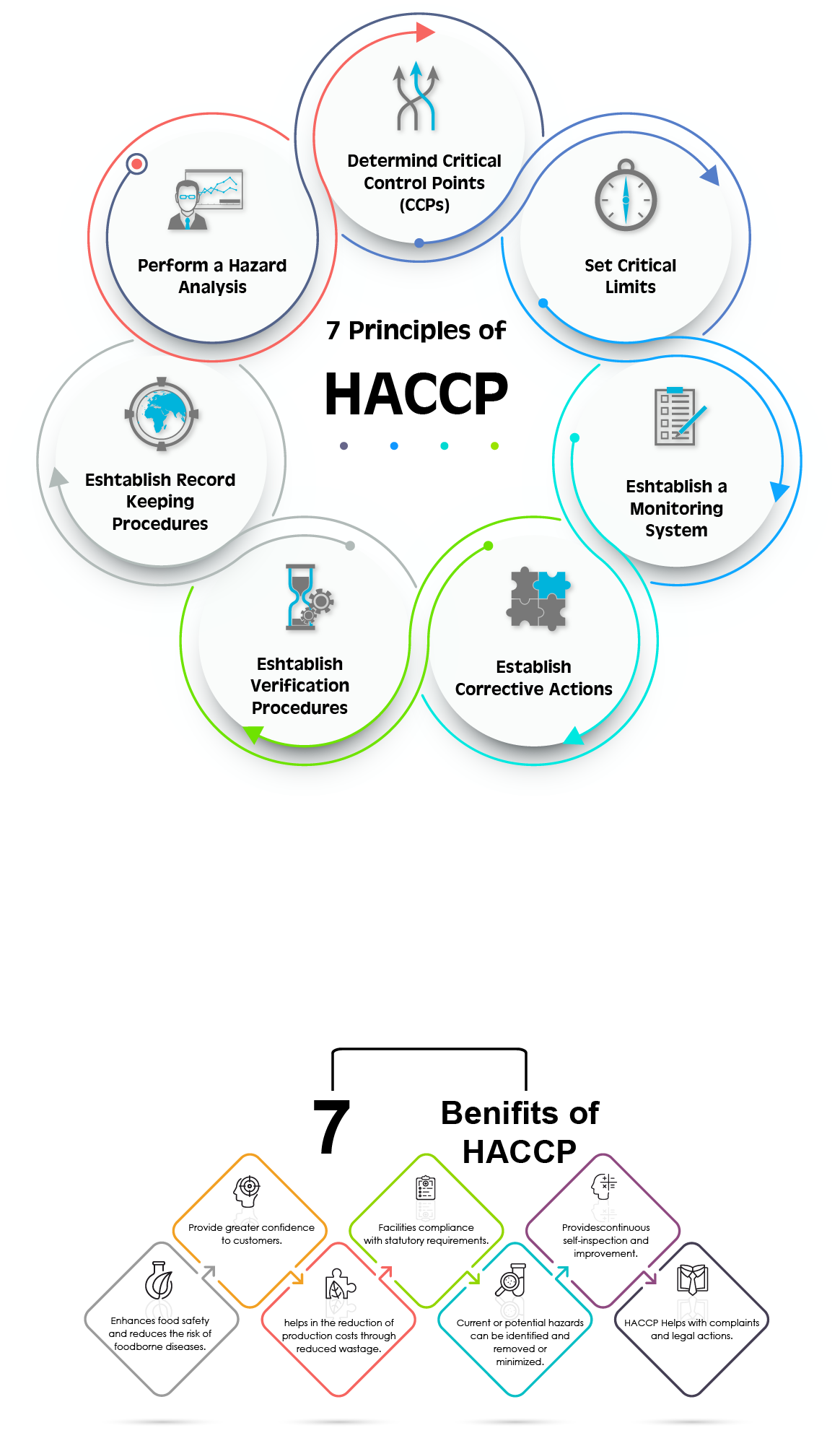

HACCP Certification

HACCP is an internationally recognized, science-based, food safety system that is used to help ensure the manufacture of safe food products.

HACCP is designed to prevent, reduce or eliminate potential biological, chemical, and physical food safety hazards, including those caused by cross-contamination.

Good Hygiene Practices (GHP)

Good Hygiene Practices (GHP) is a system for ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in any production process that can not be eliminated though testing the final product.